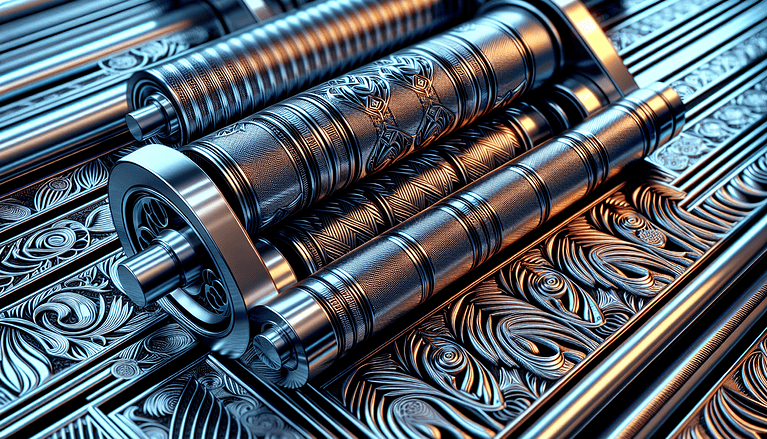

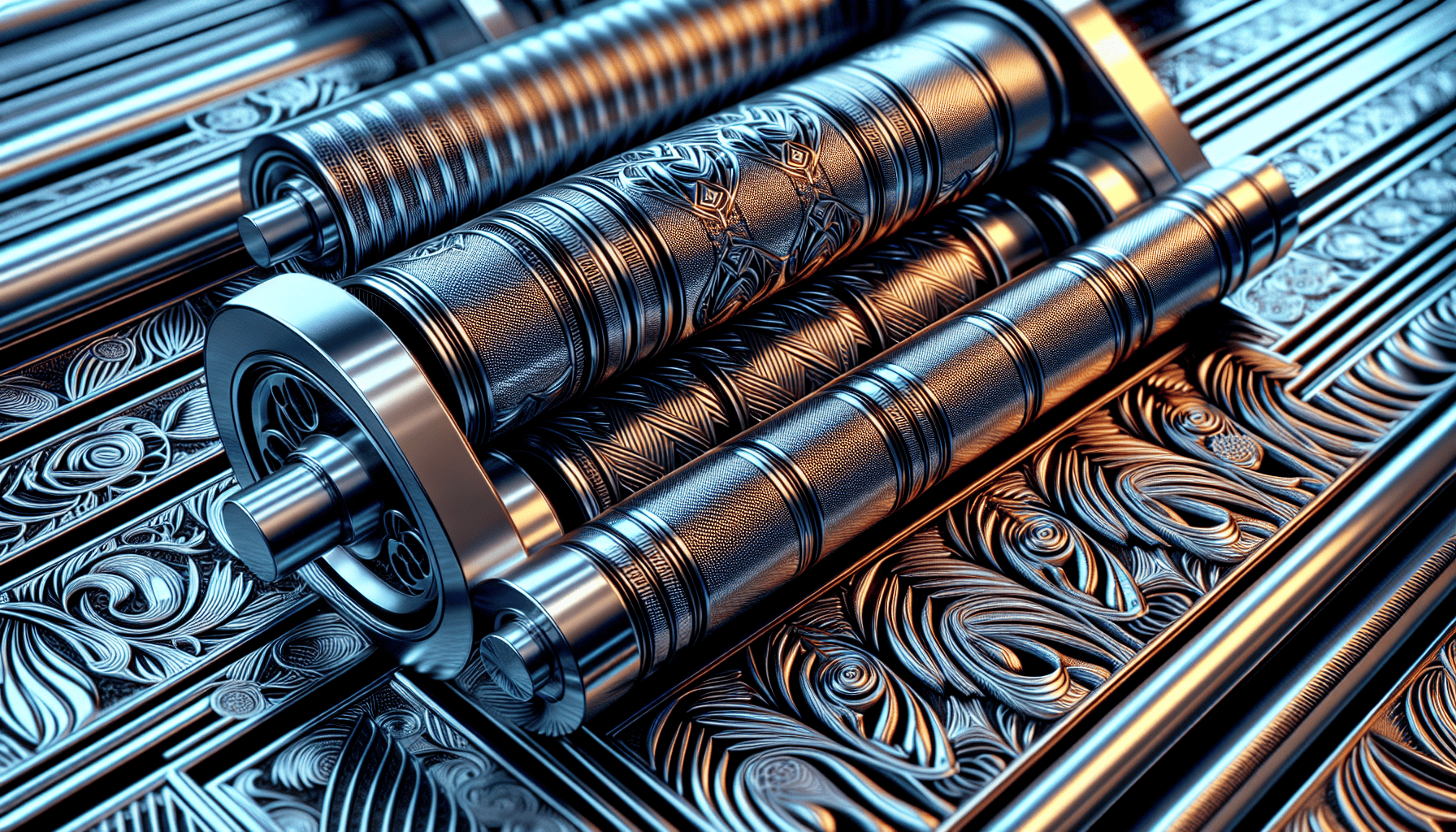

Embossing rollers represent a harmonious blend of artistry and precision within the realm of modern printing technology. These specialized tools play a crucial role in elevating the visual appeal and tactile experience of printed materials through intricate raised designs. By understanding the intricate mechanics and design considerations behind embossing rollers, we delve into a world where creativity meets technical finesse. Join us as we unravel the fascinating journey of how embossing rollers contribute to the tactile beauty and visual sophistication of printed materials in today’s digital age.

The History and Evolution of Embossing Rollers

Embossing rollers have a rich history dating back centuries, where artisans utilized manual techniques to create raised patterns on paper and other materials. The evolution of embossing rollers saw the integration of industrial machinery, leading to more efficient and precise embossing processes. Innovations in engraving technologies and materials have played a pivotal role in enhancing the intricacy and detail achievable with embossing rollers over time. As printing techniques advanced, embossing rollers became a versatile tool for adding sophistication and tactile appeal to printed products.

The Functionality and Components of Embossing Rollers:

Embossing rollers consist of intricate designs engraved onto cylindrical surfaces, allowing for the transfer of patterns onto various substrates. These rollers are typically made from durable materials such as steel or polymer, ensuring longevity and quality in the embossing process.

The Importance of Materials in Creating High-Quality Embossed Prints:

Selecting the right materials for embossing rollers is crucial in achieving desirable results. Materials such as brass, copper, and silicone offer different benefits in terms of durability, flexibility, and detail reproduction, influencing the overall quality of embossed prints.

The Role of Technology in Advancing Embossing Roller Designs:

Advancements in digital design software and precision manufacturing techniques have revolutionized the way embossing rollers are created. Modern technologies allow for intricate and complex designs to be translated onto embossing rollers with unprecedented accuracy and detail.

The Process of Creating Customized Embossed Designs with Rollers:

Crafting personalized embossed designs involves a meticulous process of digital design, engraving, and testing. Artisans work closely with clients to develop unique patterns that reflect brand identity and creative vision, ensuring a one-of-a-kind embossed result.

The Applications of Embossing Rollers in Various Printing Industries:

Embossing rollers find extensive applications in industries such as packaging, stationery, textile, and beverage labeling, adding a touch of elegance and luxury to products. From embossed logos to textured patterns, these rollers elevate the visual and tactile experience of printed materials.

The Maintenance and Care of Embossing Rollers for Longevity:

Proper maintenance and care practices are essential to prolonging the lifespan of embossing rollers. Regular cleaning, storage in optimal conditions, and periodic inspection help ensure the continued performance and quality of these precision tools.

The Future Trends and Innovations in Embossing Roller Technology:

As printing technology continues to evolve, the future of embossing rollers holds exciting possibilities. From advanced laser engraving techniques to sustainable materials, innovation in embossing roller technology is set to redefine the boundaries of creativity and precision.

Conclusion: Embracing the Artistry and Precision of Embossing Rollers in the Modern Printing Landscape:

Embossing rollers stand as a testament to the artistry and precision that define modern printing technology. Their ability to enhance the visual appeal, tactile experience, and brand identity of printed materials underscores their importance in the ever-evolving landscape of printing. By understanding the history, functionality, applications, and future innovations of embossing rollers, we gain a deeper appreciation for the craftsmanship and ingenuity that go into every embossed creation.

The Functionality and Components of Embossing Rollers

Embossing rollers are intricate tools designed to impart raised designs onto various materials, adding a tactile and visual dimension to printed products. Comprising a core shaft, an engraved surface, and a sturdy frame, embossing rollers are engineered with precision to ensure consistent and flawless embossing results. The engraved surface of the roller features intricate patterns or textures that are transferred onto the substrate with pressure. The functionality of embossing rollers relies on the application of heat and pressure, which softens the material and molds it to the contours of the roller’s surface, creating a raised impression. These components work seamlessly together to deliver intricate, customized embossed designs that enhance the aesthetic appeal and tactile experience of printed materials.

The Importance of Materials in Creating High-Quality Embossed Prints

When it comes to creating high-quality embossed prints, the choice of materials used in embossing rollers plays a crucial role. The type of material used in the construction of embossing rollers directly impacts the clarity, depth, and durability of the embossed designs. Materials with the right combination of strength, flexibility, and durability are essential to ensure precise and consistent embossing results. Additionally, the surface finish and texture of the materials used can influence the tactile feel and visual impact of the embossed prints. By selecting the appropriate materials for embossing rollers, printers can achieve impressive results with sharp details and crisp embossed patterns. Thus, understanding the importance of materials in creating high-quality embossed prints is vital for achieving optimal outcomes in the printing process.

The Role of Technology in Advancing Embossing Roller Designs

Technology has played a pivotal role in revolutionizing the design and functionality of embossing rollers in the printing industry. With advancements in precision engineering and digital imaging software, manufacturers can now create embossing rollers with intricate and complex patterns that were once unimaginable. Computer-aided design (CAD) software enables designers to meticulously craft detailed designs that are then translated into precise engraving on the embossing rollers. Additionally, advancements in materials science have led to the development of innovative roller coatings that enhance durability and performance. Furthermore, automation technologies have streamlined the manufacturing processes, allowing for faster production and customization of embossing rollers to meet the specific needs of various printing applications. As a result, technology continues to push the boundaries of embossing roller designs, offering new possibilities for creating striking and impactful embossed prints.

The Process of Creating Customized Embossed Designs with Rollers

When creating customized embossed designs with rollers, the process involves a delicate balance of artistic vision and technical expertise. Designers first conceptualize the desired embossed pattern, taking into account factors such as depth, intricacy, and texture. Next, the selected design is translated into a digital format for precision machining of the embossing rollers. Skilled technicians meticulously etch the design onto the rollers, ensuring accuracy and detail in every line and curve.

Once the embossing rollers are prepared, they are integrated into the printing press or embossing machine. Substrates are carefully fed through the machine, with the embossing rollers applying pressure to create the raised design on the material’s surface. The result is a stunning creation that showcases the artistry and precision of embossing rollers, adding a touch of sophistication and elegance to printed material.

The Applications of Embossing Rollers in Various Printing Industries

Embossing rollers find widespread applications across various printing industries, adding a touch of sophistication and elegance to diverse printed materials. In the packaging industry, embossing rollers are utilized to create eye-catching designs on product packaging, enhancing brand visibility and consumer appeal. In the stationery sector, these rollers are instrumental in producing intricately embossed patterns on notebooks, cards, and invitations, elevating the aesthetic appeal of such products. Moreover, in the textile industry, embossing rollers play a vital role in imprinting unique textures and designs on fabrics, giving them a distinctive look and feel. From advertising materials to labels and beyond, the versatility of embossing rollers enables printing industries to incorporate tactile elements that captivate the senses and leave a lasting impression on consumers.

The Maintenance and Care of Embossing Rollers for Longevity

Proper maintenance and care are essential for ensuring the longevity and optimal performance of embossing rollers in printing applications. Regular cleaning of embossing rollers is crucial to prevent buildup of ink or debris that could affect print quality. Using compatible cleaning solutions and tools helps to protect the delicate surface of the rollers. Additionally, inspecting embossing rollers for signs of wear and tear is key to addressing any potential issues early on to prevent damage. Lubricating the moving parts of embossing rollers can help reduce friction and ensure smooth operation. Implementing a maintenance schedule that includes routine checks and servicing can extend the lifespan of embossing rollers, saving costs and maintaining quality output in the long run.

The Future Trends and Innovations in Embossing Roller Technology

As the printing industry continues to evolve, the future of embossing rollers holds exciting trends and innovations. Advancements in technology are revolutionizing the design and manufacturing processes of embossing rollers, leading to greater intricacy and efficiency. With the growing demand for customized and unique printed materials, embossing rollers are adapting to offer more versatility and precision in creating elaborate designs. Integration of digital tools and automation is streamlining the production of embossed prints, reducing turnaround times and enhancing overall quality. Additionally, sustainability is becoming a key focus, driving the development of eco-friendly materials and processes for embossing rollers. The future trends in embossing roller technology aim to push boundaries, offering new possibilities for creating stunning embossed effects that captivate audiences and elevate the visual experience of printed materials.

Conclusion: Embracing the Artistry and Precision of Embossing Rollers in the Modern Printing Landscape

Embracing the artistry and precision of embossing rollers in the modern printing landscape signifies a deep appreciation for the intricate blend of creativity and technical expertise that these specialized tools embody. As technology continues to advance, the role of embossing rollers in elevating the tactile and visual aesthetics of printed materials becomes increasingly indispensable. The versatility and customization potential offered by embossing rollers empower designers and printers to create unique and engaging pieces that captivate their audience. By understanding and harnessing the capabilities of embossing rollers, the printing industry can continue to push boundaries and set new standards for excellence in print production. In conclusion, the journey of incorporating embossing rollers into modern printing practices not only enhances the overall quality of printed materials but also fosters a deeper connection between craftsmanship and innovation.

0 Comments