Embossing rollers are not just traditional tools used for creating raised patterns on paper; they are heralding a new era in printing technology. These innovative rollers are revolutionizing the printing industry by offering a wide array of applications beyond simple decorative effects. From enhancing product packaging to adding security features to documents, embossing rollers are versatile and highly customizable. Their precision and intricacy allow for intricate designs and textures, making them indispensable for businesses seeking to make a lasting impression. Join us as we delve into the cutting-edge applications of embossing rollers in modern printing.

The Evolution of Embossing Rollers in Printing Technology

Embossing rollers have witnessed a remarkable evolution in printing technology, transforming from simple tools to sophisticated instruments that revolutionize the printing process. From their humble beginnings as manual devices to the innovative automated systems of today, embossing rollers have become integral to various industries. The incorporation of advanced materials and precision engineering has elevated the capabilities of embossing rollers, allowing for intricate designs and high-quality finishes. This evolution has not only improved the efficiency of printing processes but has also expanded the creative possibilities for designers and manufacturers alike. As technology continues to advance, so too will the capabilities of embossing rollers, ensuring that they remain at the forefront of modern printing technology.

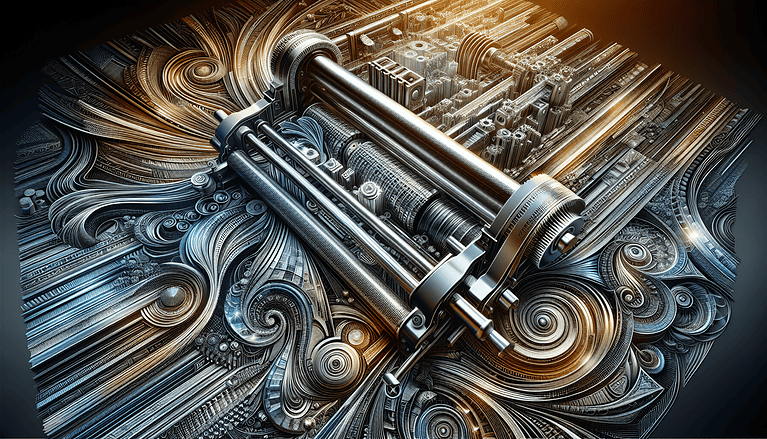

The Physical Components and Mechanics of Embossing Rollers

Embossing rollers are intricate tools that play a pivotal role in the art of creating raised patterns on various materials. The physical components of embossing rollers typically consist of a sturdy core onto which the embossing elements are mounted. These elements, known as dies, are carefully crafted to impart the desired design onto the substrate. The mechanics behind embossing rollers involve a precise interplay between pressure, heat, and material composition. As the substrate passes through the nip point between the rollers, the dies on the embossing roller press into the material, creating the raised pattern. The rollers can be customized in terms of diameter, surface texture, and pattern design to achieve specific results. Understanding the physical components and mechanics of embossing rollers is essential for achieving exceptional quality and precision in embossed printing applications.

Embossing Rollers in Product Packaging: Aesthetic and Functional Enhancements

Embossing rollers play a crucial role in elevating product packaging through both aesthetic appeal and functional enhancements. The intricate designs and raised textures created by embossing rollers can add a touch of luxury and sophistication to packaging, making products stand out on the shelves. Beyond visual appeal, embossing can also serve functional purposes such as improving grip on packaging, enhancing tactile experience, and even providing better protection for the products inside. Brands utilize embossing rollers to create unique packaging designs that resonate with their target audience, reinforcing brand identity and increasing brand recognition. The versatility of embossing rollers allows for endless creative possibilities in product packaging, making them a valuable tool for businesses looking to make a memorable impression on consumers.

Security Features: Utilizing Embossing Rollers to Deter Counterfeiting

Security features play a crucial role in protecting brands and documents from counterfeiting, and embossing rollers are at the forefront of this defense. Utilizing embossing rollers to deter counterfeiting enhances the security of products and documents by adding unique tactile elements that are difficult to replicate. The raised patterns created by embossing rollers provide a physical barrier against counterfeiters, as these intricate designs are challenging to reproduce accurately. Moreover, the precision and customization options offered by embossing rollers allow for the integration of complex security features, such as hidden patterns or microtext, further enhancing the anti-counterfeiting measures. By incorporating embossing rollers in the production process, businesses can ensure the authenticity of their products and uphold their brand reputation while safeguarding against fraudulent activities.

Customization Options: Tailoring Designs with Precision Embossing

Customization options in printing have reached new heights with the advent of precision embossing rollers. These rollers allow businesses to tailor their designs with intricate details and exquisite textures, offering a unique touch to their products. Whether it’s creating subtle patterns or striking visuals, embossing rollers provide a high level of precision that ensures every detail is perfectly replicated on the printed material. With the ability to emboss various substrates such as paper, cardboard, and even metal, the customization possibilities are endless. Brands can elevate their packaging, marketing materials, and stationery with embossed designs that reflect their individuality and attention to detail. By harnessing the power of precision embossing rollers, businesses can set themselves apart in a competitive market while offering consumers a visually appealing and tactile experience like never before.

Embossing Rollers in Specialty Printing: Foiling and Spot UV Effects

Embossing rollers play a crucial role in specialty printing techniques such as foiling and spot UV effects, elevating the visual appeal and quality of printed materials. Foiling involves applying a metallic or pigmented foil to specific areas of a design using embossing rollers, creating a luxurious and eye-catching finish. Spot UV effects, on the other hand, utilize embossing rollers to apply a glossy, raised coating to selected areas of the print, adding depth and contrast. These techniques allow for intricate detailing and customization, enhancing the overall aesthetic value of various printed products. By incorporating foiling and spot UV effects with embossing rollers, printers can produce sophisticated and premium-looking materials that stand out in the marketplace, enticing customers and making a lasting impression.

Environmental Impact: Sustainable Practices in Embossing Roller Manufacturing

When it comes to the manufacturing of embossing rollers, sustainable practices are becoming increasingly important in today’s eco-conscious world. Companies are realizing the environmental impact of their production processes and are striving to minimize their carbon footprint. Sustainable practices in embossing roller manufacturing involve using recycled materials, optimizing energy efficiency in production facilities, and reducing waste through efficient resource management. By incorporating eco-friendly materials and processes, manufacturers can significantly decrease their environmental impact and contribute to a greener future. Investing in sustainable practices not only benefits the planet but also enhances a company’s reputation as a socially responsible organization. As the demand for eco-friendly solutions grows, sustainable practices in embossing roller manufacturing will continue to play a vital role in shaping the industry’s future.

Innovative Techniques and Trends in Embossing Roller Applications

As technology advances, innovative techniques and trends are shaping the applications of embossing rollers in the printing industry. One such trend is the integration of digital embossing technology, which allows for more intricate and precise designs to be implemented with ease. Additionally, the use of advanced materials in manufacturing embossing rollers has led to improved durability and longevity, enhancing their performance in various printing processes. Another emerging technique is the combination of embossing with other finishing effects, such as foil stamping and spot UV, to create visually striking printed materials. These advancements in embossing roller applications are driving creativity and versatility in design, providing new opportunities for businesses to differentiate their products and brands in a competitive market.

Conclusion: Embracing the Future of Printing with Embossing Rollers

As we conclude our exploration of the innovative applications of embossing rollers, it becomes evident that these versatile tools are paving the way for the future of printing technology. With the ability to create intricate designs, enhance product packaging, and provide security features, embossing rollers offer a myriad of possibilities for businesses looking to make a lasting impression. By embracing the precision and customization options that embossing rollers provide, companies can elevate their branding and stand out in a competitive market. As technology continues to evolve, embossing rollers will play an essential role in shaping the landscape of printing, offering sustainable practices and cutting-edge techniques to meet the demands of the modern industry. Embracing the future of printing with embossing rollers ensures that businesses stay ahead of the curve and achieve remarkable results in their print projects.