Key Highlights

- Embossing and debossing are popular printing techniques that add a touch of elegance and sophistication to various print products.

- Embossing creates a raised design, while debossing creates an indentation.

- Both techniques utilize a metal die to mold the material under heat and pressure.

- Embossing is ideal for highlighting logos, text, or intricate details.

- Debossing offers a subtle, sophisticated look for stationery, packaging, and more.

- The choice between embossing and debossing depends on the desired visual and tactile effect.

Introduction

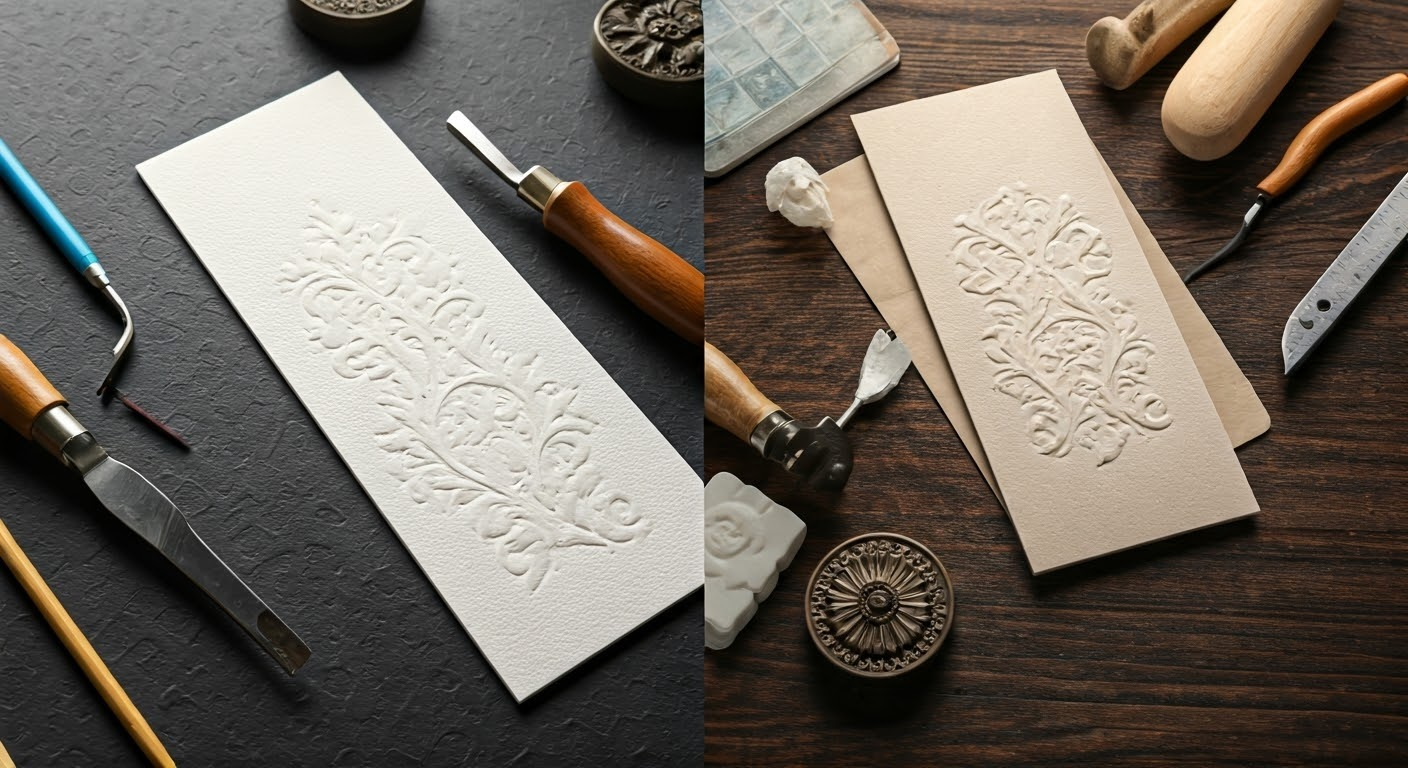

In the world of printing, where elegance and visual appeal often take center stage, embossing and debossing stand out as popular techniques used in conjunction. These printing processes add a touch of sophistication and dimension to various print pieces, creating a lasting impression. But what exactly are embossing and debossing? Let’s explore the key differences between these two fascinating techniques and understand how they enhance the overall look and feel of a product.

Understanding Embossing: The Basics

Embossing is a printing technique that involves creating a raised design on various materials, such as paper, card stock, or leather. This technique adds a three-dimensional aspect to the print piece, making it visually appealing and memorable, much like the embossed print technique. Imagine running your fingers over a business card with an embossed logo – the raised surface adds a tactile element, enhancing its perceived value and leaving a lasting impression.

Essentially, embossing involves using a metal die, a custom-made mold bearing the desired design, and pressing it onto the material under heat and pressure. This process creates an embossed design, elevating it from the surrounding surface.

The Art of Raising Designs on Surfaces

The embossing process involves a fascinating interplay of pressure, heat, and precision, often referred to as a blind emboss. It starts with the creation of a metal plate, also known as a die, engraved with the desired design. This die acts as a mold, pressing against the material to create the raised design. When the material, be it cardstock, leather, or other suitable options, is sandwiched between this metal plate and a counter die, the embossing process begins.

The application of heat and pressure allows the material to conform to the shape of the die, resulting in a beautifully raised design. This raised design, or embossed design, adds a captivating dimension to the print piece, making it stand out from the crowd. It’s worth noting that foil stamping can be combined with embossing to create a truly eye-catching effect.

Materials Suitable for Embossing

Embossing works exceptionally well on a variety of materials, each offering a unique look and feel to the final product. Card stock, with its inherent thickness and durability, is a popular choice for embossing, making it ideal for business cards, greeting cards, and invitations, often resulting in an impressive finish on the back of the card. Leather, known for its luxurious appeal, beautifully showcases embossed designs, making it a perfect choice for high-end products like journals, wallets, and belts.

Apart from card stock and leather, embossing can also be applied to materials like foil, creating stunning effects when combined with ink or a combination emboss and other printing techniques such as silk screening. To ensure the most effective embossed pieces, it’s crucial to select a detailed die and a material with enough thickness to showcase the intricate detail of the embossed graphics.

Exploring Debossing: A Detailed Look

In contrast to embossing, which produces a raised design, debossing creates an indentation on the surface of the material. This technique is often favored for its subtle elegance and understated appeal. Imagine a notebook cover with a debossed area title – the indentation adds a touch of sophistication without being overly prominent, giving it a luxurious and refined look.

Debossing, much like embossing, involves the use of a metal die. However, instead of raising the design, the die presses into the material, creating a depressed effect.

The Technique of Indenting Designs

Debossing, like its counterpart, relies on the precise application of a combination of heat and pressure. It starts with creating a metal die etched with the desired design. This die, when pressed against the material, creates the debossed design. When the material is pressed between the metal die and a counter die, the debossing process comes into play.

The carefully controlled pressure and heat cause the material to mold into the shape of the die, leaving a beautifully indented impression. This resulting debossed design, with its subtle depth, adds a touch of sophistication and tactile intrigue to the piece. The depressed effect can range from subtle to deep, depending on the design and material used.

Choosing the Right Materials for Debossing

Debossing lends itself well to a range of materials, each offering a distinct aesthetic. Paper, being a widely used material, works effectively with debossing, making it suitable for stationery items, book covers, and packaging. Leather, with its natural grain and pliable nature, takes on debossed patterns with elegance, making it ideal for high-quality goods like belts, wallets, and journals.

In addition to paper and leather, debossing can also be applied to materials with a certain thickness and flexibility, allowing the design to be imprinted effectively. This customization option makes debossing suitable for a wide array of products, from stationery to product packaging, each benefiting from its understated elegance.

Comparing Techniques: Embossing vs. Debossing

While both embossing and debossing add a unique dimension to print pieces, understanding their differences, including the imprint of the image, is key to making the right choice for a specific project. The key difference lies in the final visual and tactile experience. Embossing creates a prominent raised design that stands out, while debossing offers a more subtle and understated indented design.

Both techniques can be applied to various materials, and the choice depends on personal preference and the desired visual impact.

Visual and Textural Differences

Embossing and debossing, while utilizing similar techniques such as laser engraving, produce vastly different visual and textural results. Embossing, with its raised design, creates a noticeable bump on the material, catching light and adding a tactile element that is hard to miss. On the other hand, debossing, with its indented design, offers a more subdued and elegant appeal, adding subtle depth and shadow to the surface.

Here’s a quick comparison:

|

Feature |

Embossing |

Debossing |

|

Design |

Raised area |

Depressed area |

|

Tactile Sensation |

Noticeable bump |

Subtle indentation |

|

Visual Impact |

Bold, eye-catching |

Understated, elegant |

|

Variations |

Can be combined with foil, ink, etc. |

Blind deboss or combined with ink, foil, etc. |

Applications in Various Industries

Both embossing and debossing find their applications across various industries, enhancing the visual appeal and perceived value of a wide range of products.

Here’s a glimpse of how these techniques are used:

- Business Cards: Embossed logos or names on business cards create a memorable first impression, while debossed details can add a touch of sophistication.

- Wedding Invitations: Embossing can elevate the elegance of wedding invitations, while debossing can offer a subtle, romantic feel.

- Product Packaging: From luxury cosmetic packaging to high-end electronics, both techniques add a touch of exclusivity and enhance brand perception.

- Graphic Design: Designers leverage both techniques to create visually appealing brochures, reports, and other marketing materials.

Conclusion

In conclusion, understanding the key differences between embossing and debossing can greatly impact your design choices. While embossing creates raised designs for a more prominent look, debossing involves indenting designs for a subtle effect. Each technique offers unique visual and textural qualities with applications across different industries. By choosing the right materials and techniques, you can enhance the aesthetic appeal of your projects. Whether you opt for embossing or debossing, these methods add sophistication and tactile interest to various surfaces, making them a versatile choice for creative projects. Remember to consider your design goals and material suitability when deciding between embossing and debossing.

Frequently Asked Questions

What Surfaces Can Be Embossed or Debossed?

A variety of materials can be embossed or debossed, including card stock, paper, leather, and even some metals. These techniques are commonly seen in stationery, packaging, and on products like business cards and wedding invitations.

0 Comments